Installation & Maintenance

Master Lock provides information regarding product installation, changing combinations for built-in locks, replacement parts and product terminology.

Security Management

-

-

Master Lock maintains an extensive database on each installation to maintain high security and to make it easy to add locks to your system. Security management is crucial to an installation. Extensive user registration eliminates duplicate serial numbers within an installation and avoids key system crossover by zip code. Replacement charts and control keys can only be ordered for users of registered systems. This is imperative to a secure system.

How To Instructions

-

How to Install Your Master Lock Built-In Locker Lock

- 1600 Series Built-In Combination Installation Instructions

- 1700 Series Built-In Keyed Installation Instructions

-

How to Change Your Combinations for your Master Lock Locker Lock

- Combination Change Instructions All Built-In Combination Locks

- Combination Change Instructions All Built-In Combination Locks (except 1652) (Video)

- Combination Change Instructions NEW! 1652 Built-In Lock (Video)

Control Charting

-

For your convenience and security, Master Lock provides easy-to-use Control Charts to help you keep track of locker assignments and the corresponding combinations. Charts are supplied with all combination padlocks and Built-In combination locker lock applications.

For examples of charts, see below:

-

You can request your Control Chart electronic file with this form. Your CD will include a text file of your records.

Extension Kits

-

Master Lock extension kits allow you to install your Master Lock Built-In Locker Lock on most locker types.

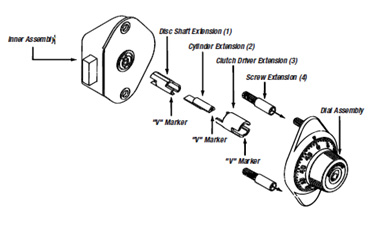

Built-In Combination Locks

Extension kit enables standard Master Lock Nos. 1630, 1652, 1654, 1655, 1670, 1671 and 1690 combination locks to operate in 11/16in (17mm) to 3/4in (19mm) thick standard locker doors.

Order No. 1654-0320

Each Set Includes:

- 1 Disc shaft extension

- 1 Cylinder extension

- 1 Clutch driver extension

- 2 Screw extensions

Assembly Instructions:

- Assemble Disc Shaft extension first, with “V” marker facing away from inner assembly. Turn part until seated into inner assembly

- Assemble cylinder extension into disc shaft extension with “V” marker facing away from inner assembly. Turn part until seated into disc shaft extension

- Assemble clutch driver extension over disc shaft extension with “V” marker facing away from inner assembly. Turn part until seated into inner assembly

- Assemble screw extensions to dial assembly

- Continue with standard Built-In combination lock installation instructions

Multi-User Locks

Extension kit enables Master Lock Nos. 3630, 3631 and 3670 multi-user locks to operate in 11/16in (17mm) to 3/4in (19mm) thick standard locker doors.

Order No. 3630-0320

Lock-Locker Compatibility Program™

-

-

The compatibility between lock and locker must be seamless, especially when locks come from Master Lock and lockers from manufacturers. We have your solution – the Lock-Locker Compatibility Program™

Master Lock, in partnership with the manufacturer, has developed an ongoing collaborative engineering and testing program, designed to help ensure the locker purchaser receives a high quality, seamless, locker locking solution.

More About Lock-Locker Compatibility Program™

Parts & Terminology

-

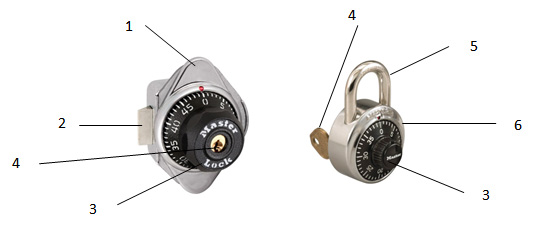

Lock Parts & Names

1. Escutcheon Plate – corrosion resistant escutcheon plate hides mounting hardware and is designed to fit virtually any locker

2. Locking Mechanism – choose from a variety of springbolt or deadbolt locking mechanisms to match your facility‘s locker styles and security requirements

3. Dial – smooth-turning dial affords quick access. Five pre-programmed combinations available at the press of a button on all Built-In combination locks.

4. Key Control Option – key control override feature allows quick access by supervisor or administrator. Available with both combination and Built-In locker locks.

5. Shackle – choose from hardened steel (1502, 1525) or hardened steel alloy (2002, 2010) for maximum resistance to cutting and sawing.

6. Case – Stainless steel outer case with cold-rolled steel inner case protects locking mechanism from severe physical attack.

-

Right- vs. Left- Hand Opening

When facing the locker, if the hinges are on the right side, it is considered a right-hand opening locker. Conversely, if the hinge is on the left, it is a left-hand opening locker. Many locks are specified for either right-hand or left-hand opening lockers, so be sure to select the correct lock when ordering.

-

Locker Lock Terminology

Key Controlled – locks which have a key override for supervisory access.

Built-In – Locks which are bolted to a locker door.

Built-In Key Lock – Locks opened with a key, which are bolted to a locker door. No combination.

Pin Tumbler Lock (1710/1714) – Locks that have a pinned keyway for higher security.

Dead Locking Latch on Bolt (1670) – Bolt which requires that the dial must be turned to engage the lock.

Springbolt (1652/1654) – Spring loaded bolt which allows the lock to be locked without turning dial.

Bolt Throw – Outward movement of bolt.

Knob and Dial Assembly on Built-Ins – See supplemental parts sheet.

Lift Latch (1630) – Vertical travel locking bolt engages lift handle locker mechanism.

Wrap-Around Latch – Convenient, automatic slam-shut locking combined with automatic and secure dead bolt locking.